Concrete Polishing

Concrete Polishing by Verona Stone

We can add a very unique and rustic yet modern look to any home, condo or office!

We can add a very unique and rustic yet modern look to any home, condo or office!

When finished properly, a durable and easy-to-live-with concrete finish is created and will shine for years. With staining and other finishes, we’re able to alter existing concrete for a customized, tailored look.

What is Verona’s Concrete Polishing Process?

- Grinding existing concrete floors using lower grit diamond discs to expose the aggregate within.

- Step-by-step, newly exposed aggregate is honed and brought up to a naturally polished finish.

- In the midst of honing, a densifier is added to seal the concrete and make it resistant to staining, wear and dust.

Residential Polished Floor Benefits:

- Cost savings: Traditional floor covering materials such as tile or wood are not necessary when the existing concrete is used as the finished floor surface.

- Longer life-cycle savings: Polished floors are not as vulnerable to damage from flooding and wear as other materials and do not ever need replacing. The only maintenance necessary is a light refinishing and re-seal every few years

- Easy to clean: Concrete is a very clean surface that with the help of a good densifier won’t harbor dust, dirt and allergens

Commercial and Retail Polished Floor Benefits:

Commercial and Retail Polished Floor Benefits:

- Cost savings: Using the slab on grade as the finished floor surface is often more cost effective than natural stone or porcelain and maintenance costs are generally lower.

- More resistant to high foot traffic than marble or wood.

- Less maintenance and longer service life: PPolished floors are generally easy to clean, requiring only regular damp mopping. They also eliminate the need for messy topical waxes or coatings which tend to wear off quite quickly and need to be re-applied.

- Resistant to moisture transmission issues: Polished concrete allows the floor to breathe and eliminates issues that arise with other flooring materials that seal off the concrete, such as tile, etc.

- High light reflectivity: Important for high end office building floors, hotels and restaurants that want to project a bright, clean, professional image. Also saves energy by reducing artificial lighting requirements.

- Is a sustainable flooring alternative: Polished concrete does not require any environmentally hazardous coatings, cleaners or adhesives. No chemicals are needed to refinish the surface.

Verona Stone’s Concrete Services

Concrete Grinding & Scarifying:

Removes grime, paint, epoxy or other topical surfaces to prepare a floor for polishing or for another type of floor to be installed on top.

Concrete Grinding & Polishing:

Removes top layer of the concrete to expose the aggregate (stones) within. Floor is then brought up to a natural polish and sealed to provide a long lasting and beautiful surface.

Polished Concrete Options

Fine Aggregate Exposure

Large Aggregate Exposure

Concrete Cleaning & Densification:

Heavy scrub of existing concrete surface using commercial scrubbing pads and descaling solution. Then a densifier is applied which penetrates into the concrete to seal it and make it resistant to dust accumulation.

Custom Concrete Staining:

We apply water or acid based dyes to achieve a very unique and custom look to your existing concrete floor. Can even used stencils to stain your companies logo into a slab of concrete. Use your imagination and let us turn a plain slab of concrete into something beautiful and unique.

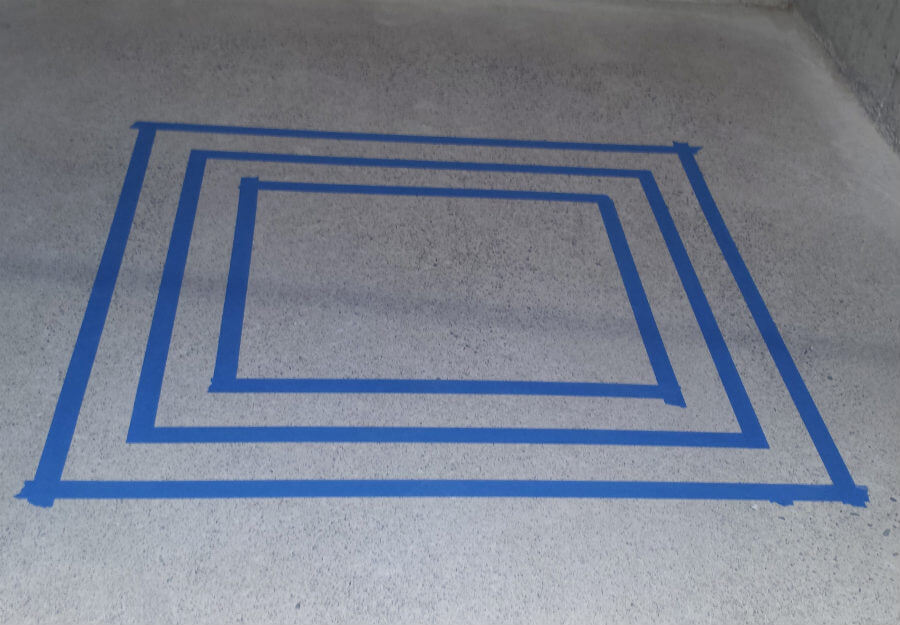

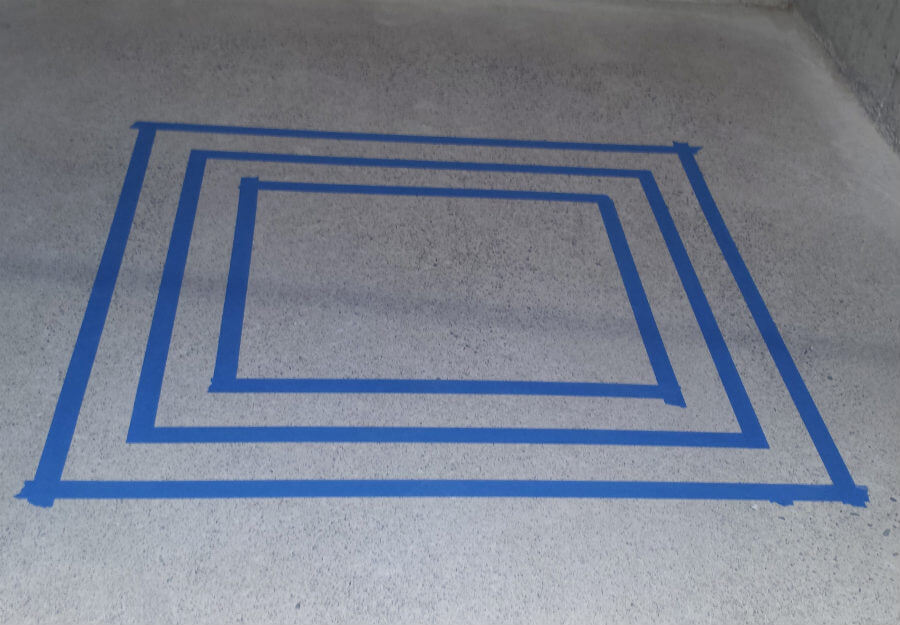

Concrete Stain Pattern

Final Stained Concrete

Garage Floor Polishing:

Let us turn that dusty and dirty garage floor into a beautiful polished floor that will resist dust accumulation and grime. Add in a coloured dye for a custom look!

We can add a very unique and rustic yet modern look to any home, condo or office!

We can add a very unique and rustic yet modern look to any home, condo or office! Commercial and Retail Polished Floor Benefits:

Commercial and Retail Polished Floor Benefits: